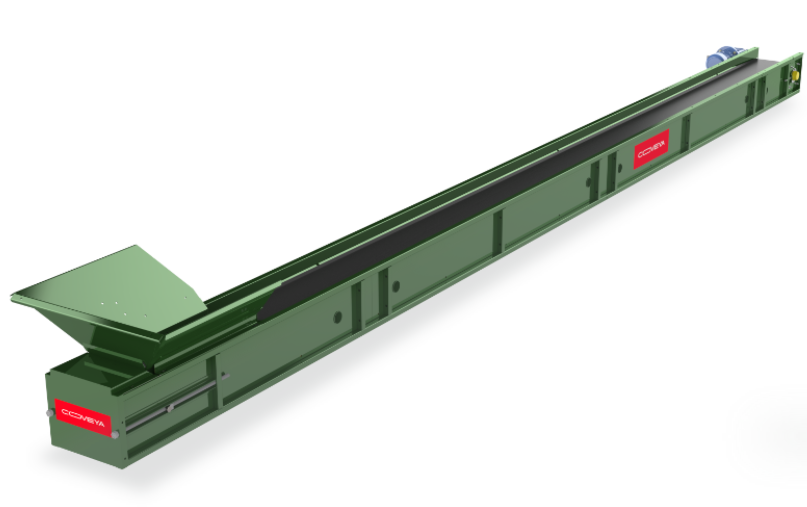

Easikit™ 300 Conveyor for the Recycling Industry

The Easikit™ 300 is the narrowest conveyor in the market, making it the perfect choice for recycling facilities with limited space.

Product overview

It is also engineered for high-performance materials handling, so you can be confident that it will get the job done, no matter how tough.

Here are just a few of the benefits of using the Easikit 300 in your recycling facility:

- Narrow design: The Easikit 300 is only 300mm wide, making it easy to navigate through tight spaces and around obstacles. This is especially important in recycling facilities, where there is often a lot of equipment and materials in a small space.

- Powerful performance: The Easikit 300 can handle a wide range of recyclable materials, including paper, plastic, metal, and glass. It can also move materials at speeds of up to 30 meters per minute, helping to improve efficiency and throughput in your recycling facility.

- Durable construction: The Easikit 300 is made with high-quality materials and components, so you can be sure it will last. This is essential in recycling facilities, where conveyors are often running for long periods of time and handling heavy loads.

- Easy to set up and use: The Easikit 300 is a modular system that is easy to set up and use, even for inexperienced operators. This can help to reduce training costs and downtime in your recycling facility.

- Safe operation: The Easikit 300 is equipped with a number of safety features to protect operators and materials. This is important in any industrial setting, but it is especially important in recycling facilities, where there is often a lot of moving equipment and materials.

Here are some specific examples of how the Easikit 300 can be used in recycling facilities:

- Conveying recyclable materials from collection areas to processing areas: The Easikit 300 can be used to convey a wide range of recyclable materials, such as paper, plastic, metal, and glass, from collection areas to processing areas. This can help to reduce labour costs and improve efficiency in your recycling facility.

- Loading and unloading vehicles: The Easikit 300 can be used to load and unload vehicles with recyclable materials. This can help to speed up the loading and unloading process and improve safety.

- Moving materials around recycling facilities: The Easikit 300 can be used to move recyclable materials around the facility, such as from a collection area to a sorting area or from a sorting area to a processing area. This can help to improve efficiency and reduce labour costs.

If you are looking for a narrow, powerful, and easy-to-use conveyor for your recycling facility, the Easikit 300 is the perfect choice for you. Contact us today to learn more about the Easikit 300 and how we can help you improve your recycling operations.

For more information on our range of conveyors call us on 0808 501 5763 or email sales@coveya.co.uk.

At Coveya, we always strive to add value by delivering more.

- We always respond to your enquiry as soon as possible, working where possible to your project timescales

- Customer Service – we pride ourselves on our exemplary customer service and after sales support

- Full installation – we take care of onsite installation, so you are ready to go

- Conveyor maintenance – We can offer expert conveyor maintenance and servicing

- Parts and support – we can supply any part you need for your conveyor and aim to dispatch parts as soon as possible

- The Coveya team are always on hand to provide guidance, support and advice

Length

Up to 25m

Belt width

300mm

Max throughput

20 Tons p/h Tons p/h

-

Specification

-

Support & Maintenance

-

-

Industry

Animal feeds & agriculture, Building & construction, Composting & biomass, Demolition, Excavation

-

Power supply

110v, 240v and 415v

-

Type of material

Aggregate, Small rubble, Soil and General Waste

-

Loading method

By hand, Small machine, Wheelbarrow

-

Mobile or static

Static

-

Length

Up to 25m

-

Weight

Variable 60kg/m

-

Belt width

300mm

-

Belt speed

0.3 - 0.9m/p/s

-

Maximum throughput

20 Tons p/h Tons p/h

-

Hopper size (if used)

750x800

-

-

Service type Rental support Sales support Full installation - We take care of onsite installation so you're set up and ready

Maintenance options - We can offer the right servicing and maintenance for you

Dedicated service team - Our dedicated service team is here to help with any conveyor issues when you need us

Scheduled servicing - We'll schedule onsite service visits every 4 weeks and maintenance during downtime

Spare parts… fast - Extensive spare parts stock and unmatched lead times to keep you moving

-

Specification

-

Industry

Animal feeds & agriculture, Building & construction, Composting & biomass, Demolition, Excavation

-

Power supply

110v, 240v and 415v

-

Type of material

Aggregate, Small rubble, Soil and General Waste

-

Loading method

By hand, Small machine, Wheelbarrow

-

Mobile or static

Static

-

Length

Up to 25m

-

Weight

Variable 60kg/m

-

Belt width

300mm

-

Belt speed

0.3 - 0.9m/p/s

-

Maximum throughput

20 Tons p/h Tons p/h

-

Hopper size (if used)

750x800

-

-

Support & Maintenance

Service type Rental support Sales support Full installation - We take care of onsite installation so you're set up and ready

Maintenance options - We can offer the right servicing and maintenance for you

Dedicated service team - Our dedicated service team is here to help with any conveyor issues when you need us

Scheduled servicing - We'll schedule onsite service visits every 4 weeks and maintenance during downtime

Spare parts… fast - Extensive spare parts stock and unmatched lead times to keep you moving