- Volkan

- May 3, 2017

Conveyor belt safety: Know your nip points

A nip point (or pinch point) is a hazardous area of a conveyor belt where moving parts meet and can cause injury. To stay safe when operating a conveyor, you need to know the nip points. This article explains what nip points are and the nip hazard locations you need to be aware of, and includes vital health and safety tips to help reduce the risk of injury when working with conveyor belts.

Many opinions exist regarding what constitutes a ‘Nip Point’ on a conveyor. Unguarded and exposed ‘nip points’ lead to many unnecessary injuries, some of which sadly, can even be fatal.

It is absolutely imperative that conveyor owners and operators know what these are and ensure that they are satisfactorily guarded.

The European Standard (BS EN620:2002 +A1:2010) ‘Continuous handling equipment and systems – Safety and EMC requirements for fixed belt conveyors for bulk materials’ defines a ‘Nip point’ as the following: –

‘Dangerous point which occurs on the in-running side at the line of contact between the conveyor belt and rotating pulley and in certain cases between belt and an idler roller or a fixed part’

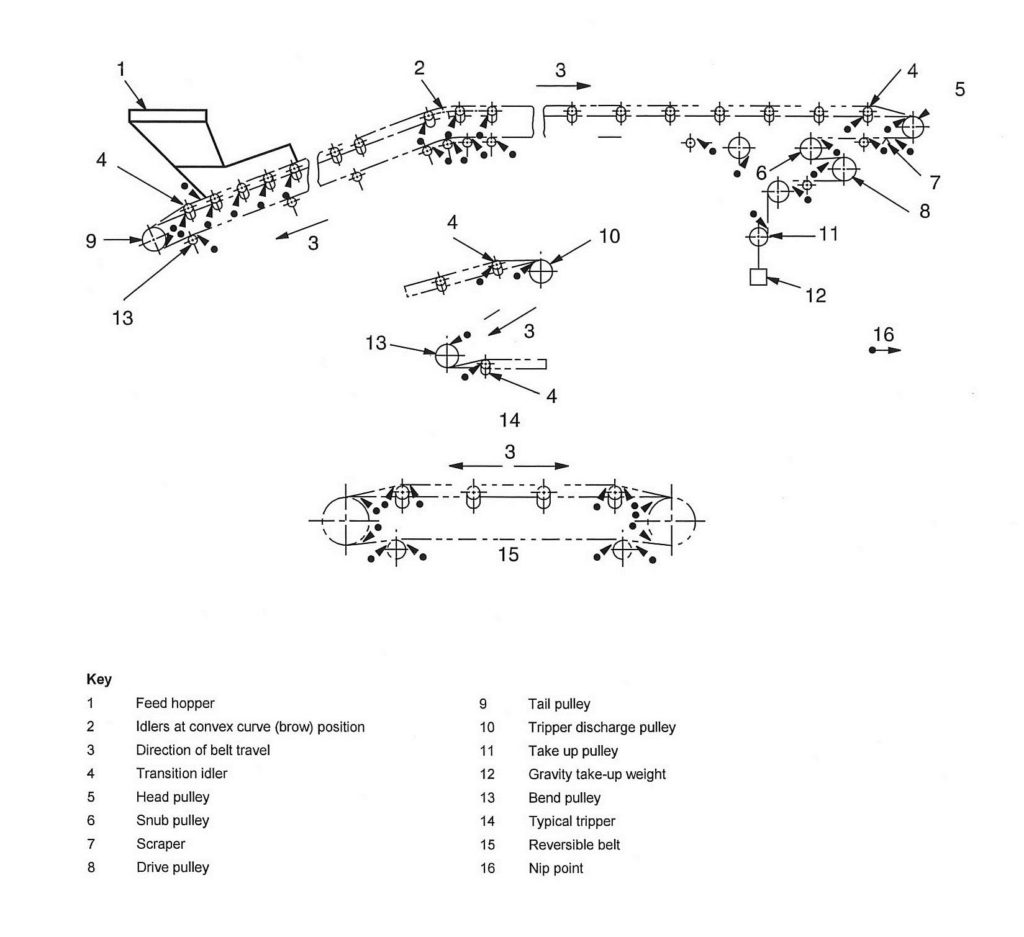

The following are the ‘Typical nip points’ as shown in the standard:

Although conveyor manufacturers provide a variety of guarding options to cover these dangerous ‘nip points’, there are too many conveyors in operation where suitable guarding hasn’t been fitted and accidents are simply waiting to happen.

Typical guarding of the return rollers will have a solid panel directly under the roller with mesh panels in between, allowing any material on the returning belt to fall through. Guards should be positioned sufficiently far enough away so that it is impossible even for the longest fingers to touch the belt and rollers.

Ensure your conveyors are safe to use. You can buy guarding, but not replacement lives/limbs!

DON’T TAKE THE RISK!